Leave Your Message

In today's rapidly evolving automotive industry, optimizing global procurement strategies is imperative for manufacturers seeking to enhance competitiveness and innovation. The Volkswagen T-Roc, a standout in the compact SUV market, represents a significant opportunity for implementing smart sourcing solutions. According to a report by McKinsey, companies that leverage advanced procurement strategies can achieve cost reductions of up to 20%, while also improving supplier relationships and driving quality enhancements. Furthermore, a study from Deloitte indicates that 60% of procurement leaders plan to invest in digital technologies to streamline their operations, underscoring the necessity for organizations like Volkswagen to adopt sophisticated sourcing techniques. By focusing on the T-Roc as a focal point, businesses can not only optimize their supply chains but also ensure that they are well-equipped to respond to market demands and consumer preferences in a digital age.

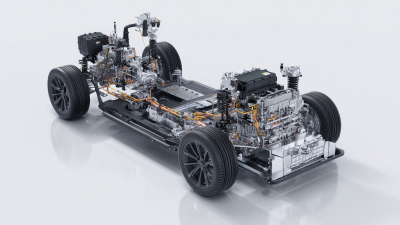

In the competitive automotive landscape, the Volkswagen T-Roc stands out not just for its design and performance but also for its innovative approach to procurement. Embracing cutting-edge digital techniques, Volkswagen is transforming its sourcing processes to enhance efficiency and adaptability. By leveraging big data analytics, the procurement teams can now predict market trends, optimize inventory levels, and significantly reduce lead times, ensuring that the T-Roc remains ahead of the curve in a rapidly changing industry.

Further, the integration of artificial intelligence and machine learning into procurement strategies is revolutionizing decision-making. These technologies enable a more precise analysis of supplier performance, leading to better negotiations and stronger partnerships. Digital platforms that consolidate supplier information and performance metrics allow Volkswagen to make informed choices, ensuring that all components meet the high standards required for the T-Roc. As a result, the procurement process becomes not just a function of supply and demand but a strategic advantage in enhancing product quality and customer satisfaction.

This bar chart illustrates the procurement costs associated with different suppliers for the Volkswagen T-Roc. It provides a visual representation of how sourcing strategies can be optimized by evaluating supplier costs effectively.

In the fast-evolving landscape of global manufacturing, the utilization of big data analytics has emerged as a pivotal strategy to enhance supply chain efficiency. As industries embrace the principles of Industry 4.0, understanding and interpreting complex data sets is no longer optional; it has become essential for maintaining a competitive edge. The manufacturing market, projected to grow from $6.94 billion in 2024 to $7.94 billion in 2025, indicates a robust demand for innovative solutions that harness big data to streamline procurement processes, from sourcing to delivery.

By leveraging advanced analytics, businesses can gain insights into supplier performance, inventory levels, and market trends. This allows for more informed decision-making and serves to mitigate risks associated with supply chain disruptions. Additionally, integrating technologies such as deep learning can facilitate better forecasting, ensuring that organizations can adapt to seemingly erratic demands. As companies look to optimize their procurement strategies, those that effectively implement big data-driven solutions will find themselves at the forefront of industry transformation, poised for sustained growth and success.

In the automotive industry, the shift towards sustainable sourcing practices has become imperative, particularly for manufacturers like Volkswagen, which aim to balance efficiency with environmental responsibility. According to a report by the World Economic Forum, over 50% of automotive leaders believe that adopting sustainable sourcing strategies can significantly enhance brand reputation and customer loyalty. As consumer demand for eco-friendly vehicles rises, investing in sustainable supply chains is not just a trend but a strategic necessity.

For the Volkswagen T-Roc, implementing sustainable sourcing solutions can involve prioritizing materials that are either recycled or derived from renewable resources. A study from McKinsey & Company projects that sustainable materials could account for up to 40% of the total material cost by 2030, emphasizing the economic viability of green sourcing practices. By embracing these strategies, Volkswagen can not only reduce its carbon footprint but also position itself as a leader in the sustainable automotive market, appealing to environmentally-conscious consumers while adhering to increasingly stringent regulatory standards.

Strategic supplier partnerships play a pivotal role in enhancing the global reach of the

Volkswagen T-Roc. In today’s competitive automotive market, building robust relationships

with suppliers is essential for streamlining operations and securing high-quality components. By collaborating closely with suppliers,

Volkswagen can leverage their expertise and insights, paving the way for innovative solutions that align with the

brand’s vision for sustainability and performance. This synergy not only boosts efficiency but also promotes agility in responding to

global market demands.

Strategic supplier partnerships play a pivotal role in enhancing the global reach of the

Volkswagen T-Roc. In today’s competitive automotive market, building robust relationships

with suppliers is essential for streamlining operations and securing high-quality components. By collaborating closely with suppliers,

Volkswagen can leverage their expertise and insights, paving the way for innovative solutions that align with the

brand’s vision for sustainability and performance. This synergy not only boosts efficiency but also promotes agility in responding to

global market demands.

Moreover, these strategic alliances facilitate expansion into new markets. As the T-Roc seeks to gain traction internationally, having

dependable suppliers in key regions can significantly reduce lead times and logistical challenges. By integrating local suppliers who

understand regional customer preferences and regulatory requirements, Volkswagen can tailor the T-Roc’s offerings to meet diverse market

needs, thereby enhancing customer satisfaction. Ultimately, strengthening these partnerships enables Volkswagen to elevate its

procurement strategy, positioning the T-Roc as a formidable player in the global automotive landscape.

In the ever-evolving landscape of automaking, the adoption of AI-driven forecasting is reshaping procurement strategies, particularly for industry giants like Volkswagen. By harnessing the power of artificial intelligence, companies can better anticipate market demands, streamline supply chains, and optimize resource allocation. This technological integration enables them to make informed decisions, reduce costs, and minimize wastage, ultimately leading to a more efficient procurement process that aligns with the dynamic nature of consumer preferences.

Moreover, AI-driven forecasting facilitates real-time data analysis, allowing for agile responses to market fluctuations. As the automotive sector faces challenges such as supply chain disruptions and shifting economic conditions, the ability to predict requirements accurately becomes invaluable. Volkswagen T-Roc, with its unique market position, can leverage these advanced capabilities to enhance its global procurement strategy, ensuring that production schedules meet customer demand without overcommitting resources. Through smart sourcing solutions powered by AI, Volkswagen can not only elevate its operational efficiency but also strengthen its competitive edge in the automotive market.

| Supplier Region | Material Type | Quantity (units) | Lead Time (weeks) | Cost ($) | Forecast Accuracy (%) |

|---|---|---|---|---|---|

| Europe | Steel | 5000 | 8 | 10000 | 95 |

| Asia | Plastic | 3000 | 6 | 15000 | 90 |

| North America | Rubber | 2000 | 4 | 8000 | 85 |

| South America | Glass | 1500 | 5 | 12000 | 92 |